ISLAND ORCHARD CIDER INTRODUCING VINEGAR PRODUCT

edible Door archive from 2019 and refreshed in 2024 for edibleNEW launch

Cider maker Bob Purman is using two parts chemistry and one part wily Mother Nature to make vinegar at Island Orchard Cider in Ellison Bay for the 2019 season. Bob’s a bit of a chemist himself, in addition to being a tinkerer. Adding vinegar to IOC’s repertoire of brews involved Bob building his own vinegar generator, cobbled together with equipment from the beer and wine industries.

“Building the generator took a lot of experimenting to get it functional,” Bob said. “It’s challenging inventing a small-scale product yourself. All cider eventually wants to be vinegar. This was a natural progression for us. We had the bottling equipment, the fruit, and kept asking ‘What else can we make with what we have?’ Vinegar was a natural extension of what Island Orchard Cider is already doing.”

Bob’s been working out his vinegar recipe for the past three years, processing small amounts using the French Orléans method, or surface method. This involves exposing alcohol to oxygen to grow acetobacter – the ‘mother’– on the surface. It’s the opposite of wine fermentation, Bob explained. Wine is enclosed during fermentation to keep out any unwanted or uncontrolled additions. The Orléans method provides the potential development of more complex flavors in the vinegar.

The fermenter Bob built was originally developed by a German chemist. “There’s a lot more craft vinegar-making going on in Europe than the U.S.,” Bob said.

In May, Bob and his wife/business partner, Yannique, visited the Pays d’Auge region of Normandy in France to explore La Route du Cidre (The Cider Route).

French cideries are the inspiration for Island Orchard Cider and the new Island Orchard Vinegar Bob is crafting. High residual sugar (HRS) vinegar is his focus, using similar processes to the hard cider Island Orchard Cider brews. All the sugar in the vinegar is naturally occurring; no additional sugar is added during the fermentation process, or after. The apples Bob uses are specific cider varietals that he grows in his orchard on Washington Island. He sources the cherries and pears from Door County orchards.

“Similar to the way IOC makes ice cider, we concentrate the fruit juice base so the end product has high residual sugar. The juice then wild ferments for about four months and stops fermenting itself. Then acetobacter is added to begin the vinegar fermentation process.”

HRS vinegar’s cousin is balsamic or aceto balsamico. Traditionally, balsamic vinegar is made from fermented grape must, concentrated syrup made from boiled down grape juice that concentrates and caramelizes the sugars. Bob’s using apples, pears and cherries and boiling down their juices into concentrations to ferment.

Island Orchard Vinegar will have similar qualities to balsamic with Door County twists. He is making six different vinegars for 2019, one of which will not have caramelization: pear.

“The pear vinegar is about freshness,” Bob said. “It’s lighter, there’s less starting acid. The pear vinegar has an awesome lightness, it will be great in summer cocktails!”

To age the Apple Maple Vinegar, Island Orchard Vinegar uses bourbon barrels from Kentucky. He first uses the barrels to age cider, then the barrels get a third life and are used to age vinegar. The barrels and maple syrup give the Apple Maple Vinegar a smoky sweet taste that is delicious in sauces and glazes. None of Island Orchard Cider’s vinegars have flavorings added after fermentation, they’re al naturale. Bob is projecting he will make 400 gallons of vinegar in 2019 and will scale up production in the coming years and with customer demand.

In addition to the Cherry, Pear, Apple Maple, Barrel Aged Apple Cider, and Sweet Apple Cider vinegars, Bob also teased that he’s fermenting a Spruce Tip Apple Cider Vinegar, another vinegar that will likely show up in cocktail menus around Door County this summer.

Island Orchard Vinegar’s handcrafted vinegars will be available for purchase mid-summer 2019. Find and sample each at Island Orchard Cider in Ellison Bay, at grocers in Door County or select locations in Milwaukee. For more details on Island Orchard Cider and Vinegar, visit their website: IslandOrchardCider.com.

“The pear vinegar is about freshness. It’s lighter, there’s less starting acid. The pear vinegar has an awesome lightness; it will be great in summer cocktails!” — Bob Purman, Island Orchard Cider

A ROCKIN' BOTTLE OF CIDER

Limited Edition Hard Cider Sales to Benefit GEO-DC

Island Orchard Cider owner and chief cider maker Bob Purman checks product.

Island Orchard Cider owner and chief cider maker Bob Purman checks product.

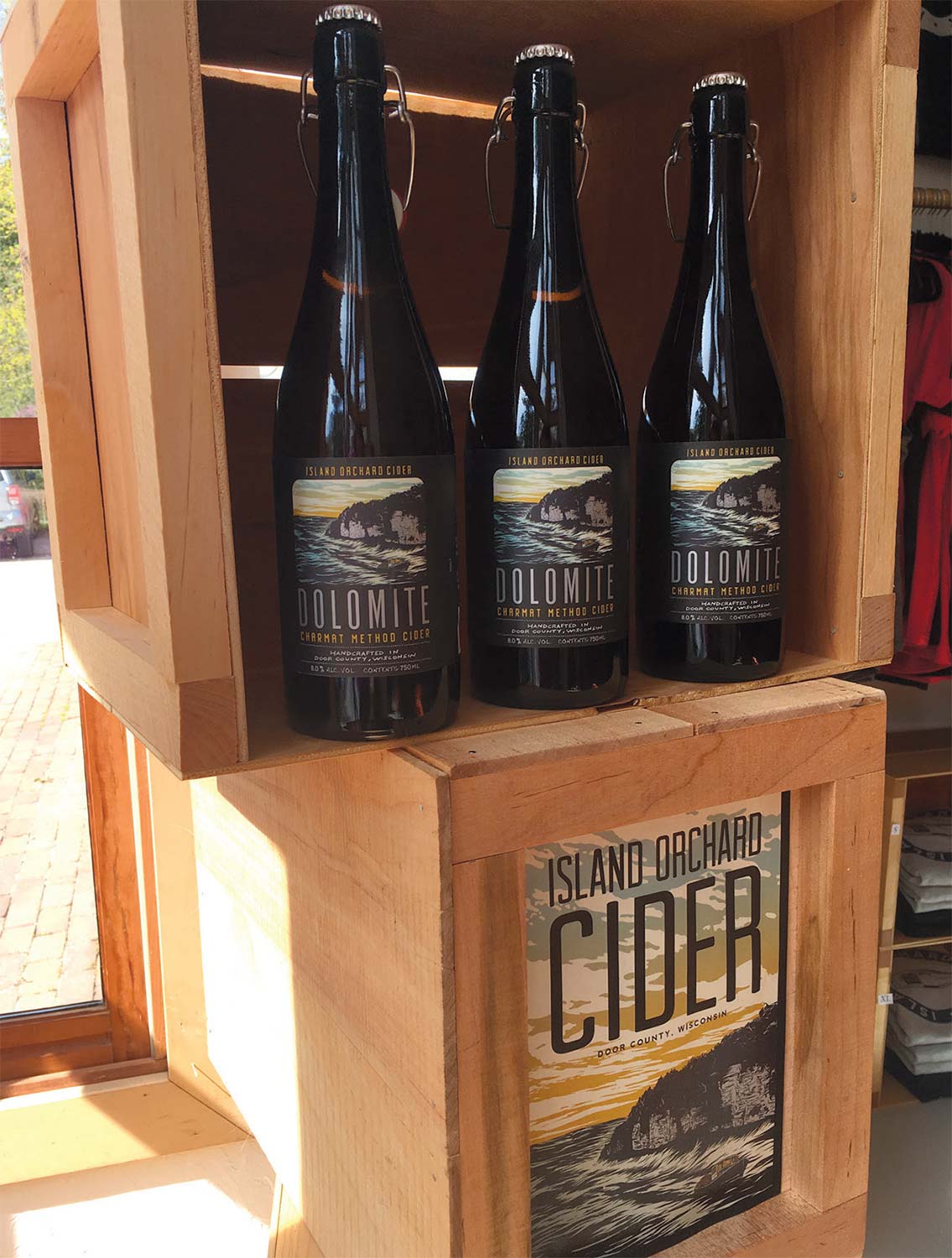

Cheese tanks have new life as hard cider pasteurization tanks at Island Orchard Cider (IOC) in Ellison Bay. This year, they’re helping craft a special edition hard cider, “Dolomite,” in honor of the stone that is the bedrock of Door County and the Niagara Escarpment.

Dolomite was handcrafted using the Charmat (Tank) method, a technique used when making the Italian Prosecco, explained Island Orchard Cider owner and chief cider-brewer Bob Purman; The Charmat method works beautifully to produce fine bubbles in a sparkling hard cider.

The sale of this limited release hard cider at IOC will benefit GEO-DC and the future construction of a Niagara Escarpment Discovery Center in the Town of Liberty Grove. IOC will donate a percentage of sales from each bottle to the nonprofit GEO-DC. The organization works to educate and highlight the ribbon of cliffs on the western side of the Door Peninsula that are the western terminus of the 1,000-mile-long Niagara Escarpment (eastern terminus is Niagara Falls).

The Niagara Escarpment terminates its mainland connection in the Town of Liberty Grove. The Discovery Center will provide indoor and outdoor learning opportunities for people of all generations to learn about, experience and love the unique natural attractions of the Niagara Escarpment.

The Macintosh apple is the primary base fruit for Dolomite. Macintosh is an aromatic apple with a high sugar level and sub acid, Purman explained. IOC presses the Macs late in the season and allows the juice to freeze. The 13% sugar content concentrates to 18% sugar and flavor in this hard cider. The juice is wild fermented for three months in a cold room, where it then becomes hard cider. Island Orchard Cider does not add any sugar to Dolomite, all sugar content comes from the fruit itself. Naming this limited-edition hard cider was easy for Purman.

“We’re standing on Dolomite, on the Niagara Escarpment,” said Purman. “When we started our orchard on Washington Island, we discovered that the soil structure is similar to the soil found in the Normandy region of France. Normandy is known for its cider apples and hard cider production.”

Island Orchard Cider is only bottling 240 gallons in 2019 and will only be selling Dolomite at the cider house in Ellison Bay. For more info, islandorchardcider.com.

“When we started our orchard on Washington Island, we discovered that the soil structure is similar to the soil found in the Normandy region of France.” — Bob Purman, Island Orchard Cider